As we observe World Food Day on 16th October, it is vital to highlight Caterglobe’s commitment to maintaining stringent food safety standards during the installation of commercial catering equipment. Food safety is not just a regulatory requirement but a moral obligation in our industry, and Caterglobe is dedicated to providing solutions that ensure a safe and hygienic kitchen environment from the outset.

The Importance of Food Safety in Equipment Installation

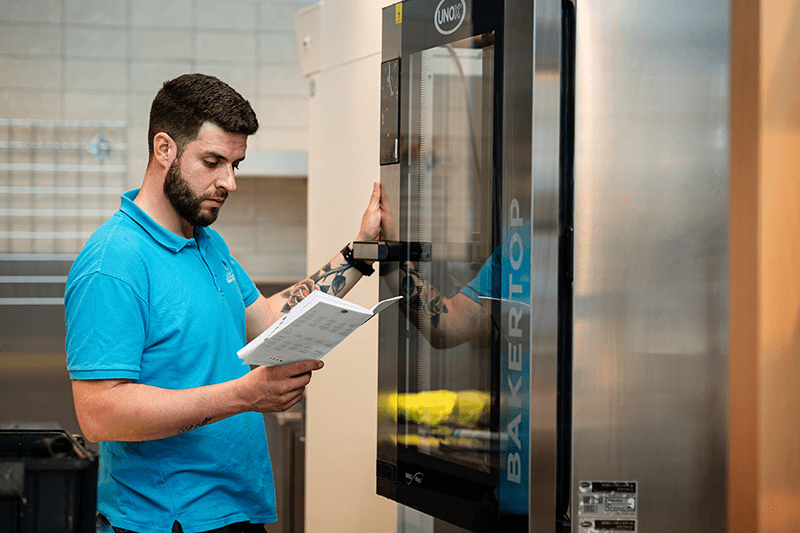

Catering equipment plays a significant role in food safety, and improper installation can lead to contamination, inefficiencies, and safety hazards that could jeopardise the health of both staff and customers. Caterglobe understands the seriousness of these risks and integrates food safety into every step of our service. Our engineers follow strict guidelines that prevent cross-contamination, bacteria build-up, and ensure our equipment functions in full compliance with health and safety standards.

Extensive Training and Expertise of Our Engineers

Caterglobe’s engineers are not only experts in the technical aspects of installation but are also extensively trained in food safety protocols. This training covers:

- Food Hygiene Legislation: Our engineers are knowledgeable about the most up-to-date regulations, including those from the Food Standards Agency (FSA), ensuring our clients are compliant with UK laws and best practices.

- Best Practices for Installation: Each type of catering equipment, whether it’s a refrigerator, oven, or dishwasher, comes with unique installation requirements. Our engineers are keen to follow power, water, and ventilation requirements and maintain the best practices.

- Electrical Supply: Verify that the site has the necessary electrical capacity and correct voltage for each piece of equipment.

- Gas Supply: Ensure that gas connections are safely installed and meet local regulations, particularly for gas ovens and grills.

- Plumbing: Ensure appropriate plumbing for water-based equipment, like dishwashers and ice machines, and proper drainage.

- Ventilation and Extraction: Install proper ventilation and extraction systems to remove smoke, heat, and odours, ensuring compliance with health and safety regulations.

- Sanitisation Before Installation: Before any equipment is installed, our engineers ensure that it is thoroughly sanitised to reduce the risk of contamination. This involves using approved cleaning solutions and wearing disposable gloves to maintain hygiene.

- Prevention of Cross-Contamination: Caterglobe takes proactive steps to avoid cross-contamination during installation, such as using colour-coded tools and cleaning supplies for different tasks, and ensuring allergens or bacteria are not transferred from one area to another.

Tailored Solutions for Every Client

No two kitchens are alike, and each client’s needs vary based on the size and scope of their operations. Caterglobe takes the time to assess each kitchen environment and ensures the equipment is installed to meet the specific safety and hygiene requirements. This includes:

Proper Ventilation: A well-ventilated kitchen is key to preventing the build-up of harmful fumes and moisture, which can lead to mould and sanitation issues. Our engineers expertly install ventilation systems that meet health and safety guidelines.

Appropriate Spacing of Equipment: Correct spacing of equipment is essential for preventing accidents and maintaining hygiene. Our engineers ensure that all machinery is installed with adequate space to allow easy cleaning and maintenance, minimising risks of contamination.

Post-Installation Safety Checks and Maintenance

Once the installation is complete, our team conducts a series of checks to ensure everything functions as intended, including:

Temperature Calibration: We meticulously calibrate cold storage equipment, such as refrigerators and freezers, to meet the recommended temperatures for food safety.

Operational Testing: All equipment is rigorously tested to ensure it operates correctly. This guarantees that kitchen staff can prepare and store food safely without risk of contamination.

Staff Training: Our engineers don’t just install the equipment—they also take time to train kitchen staff on proper operation, cleaning routines, and troubleshooting techniques to maintain safety standards.

Continuous Commitment to Food Safety

Caterglobe’s dedication to food safety doesn’t stop after installation. We offer maintenance services to ensure the ongoing safety and performance of our equipment. Regular maintenance helps prevent breakdowns that could compromise kitchen hygiene and ensures equipment continues to meet food safety standards throughout its lifespan.

Conclusion

At Caterglobe, we recognise that food safety is essential to providing a quality service in the food industry. Our engineers bring expertise, precision, and a thorough understanding of food hygiene standards to every installation, ensuring that each piece of equipment supports safe and efficient food preparation.

This World Food Day, we proudly reaffirm our commitment to supporting the food industry with top-tier equipment installations that prioritise hygiene, safety, and reliability, ensuring our clients can deliver safe, high-quality food to their customers.